What is a CMMS Software?

CMMS stands for – Computerised Maintenance Management System

Productivity depends on a qualified workforce, efficient machinery, and proper coordination on every level in an organization. If everything is running smoothly, the output continues.

Still, productivity has an archenemy, and that is downtime. Interruptions in the production cycle resulting from faulty equipment not being maintained in a timely fashion can paralyze an entire manufacturing system.

Lowered efficiency is a budget burden, and most modern companies are tackling the maintenance issues with a Computerised Maintenance Management System (CMMS).

With a CMMS, old fashion paper spreadsheets are being replaced by automated software that manages every segment of maintenance operations.

For businesses who are looking to get aboard the CMMS train, here’s everything to know about how a CMMS works and the problems it solves.

What is a CMMS Software? Benefits of CMMS Integration.

Unplanned downtime costs money, and research shows that about 82% of companies have experienced at least a single downtime incident they had not foreseen in the past three years.

The cost of lost productivity varies depending on the scale of the business model. On average, it’s believed that when manufacturing companies experience downtime, they can lose up to £300,000 per hour.

These problems aren’t localized but reverberate across the entire organisation. Companies are increasingly focusing on CMMS integration to act preventively.

At its core, a CMMS is a database ensuring the correct measures get performed at the right time. The system comes packaged as software that enables businesses to manage and streamline maintenance operations.

There are different versions of the concept. Some are industry-specific, while others are proprietary applications created for a specific company and its needs. CMMS software solutions with a more general approach are also available and easily adaptable to different businesses.

No matter its form, the function of a CMMS is to handle the potential maintenance chaos by focusing on a few key areas, such as:

- Workflow management;

- Asset visibility;

- Safety environment;

- The increased service life of machinery;

- Decrease manual work input;

- Managing field workforces;

- Holds the team accountable.

What is a CMMS Software? How Does a CMMS Work?

The idea behind the CMMS is not new. Preventive technical methods have been around for over half a century. What is new is the replacement of punch cards and old-style mainframe computers, accessible only to big corporations with modern systems that are mobile-friendly, AI-supported or that use machine learning to expand their predictive capabilities.

Newer versions are cloud-based and offer unprecedented mobility and data security.

The platforms get structured around a robust user-friendly interface that can get mastered equally fast by entry-level technicians and senior management. The software can get accessed on a PC or a smartphone and tablet. Because information is stored on the cloud, changes in the database get automatically updated in real-time and are evident for all CMMS users.

For example, when a maintenance manager alters the priority level of a specific work order, technicians responsible for that assignment will immediately receive the change. This functions both ways, after a technician completes a work order, the supervising manager will automatically be notified of the new status of the work order, and the system archives the task as completed.

Most providers offer continuous education resources, teaching clients how to use the system.

At the same time, high-end CMMS software comes with certification courses. Because the application is accessible on a mobile device, most users will be able to intuitively navigate the features and benefit from the centralized system.

Resource Planning

What is a CMMS Software? What are the Applications of a CMMS? (Maintenance Management Software)

Most Computerised Maintenance Management Systems offer a similar set of features and solutions. It tends to be a flexible system, with the key difference between providers being in how the options are implemented. The heart and soul of the software is the database that collects all relevant information and simplifies the workflow.

Some of the typical applications of a CMMS are:

Maintenance calendar: The CMMS software provides insight into maintenance resources and effectively performs the scheduling of assignments. Updates get automatically made as staff or inventory changes, and the system schedules preventive work orders.

Labour management: The system delegates tasks and assembles teams by coordinating work shifts. It so ensures every employee gets properly utilized and that all job requirements are seen through.

System monitoring: Prevention is key to long-term sustainability, but this is only an option with certain aspects. It’s important to know if a problem is on the horizon, and that’s possible with constant monitoring of the performance of the entire technical infrastructure. When a potential problem is identified, alarms are raised, and plans get formulated to counter the emerging issue.

Inventory management: Repair operations require material and equipment, typically housed on-site. The system expedites the distribution of supplies from storage facilities and issues orders for resupply.

Reporting and auditing: Data is a driving factor in any business sector, and reports are a key tool in categorising and assembling available materials and labour. Analyzing past performances makes it possible to optimize future operations and cut costs. The best CMMS enables the creation of custom KPI reports.

There are numerous advantages of using a CMMS. However, not every application is built the same. When selecting the appropriate option, it’s crucial to be diligent and filter out the best-required parameters without compromising.

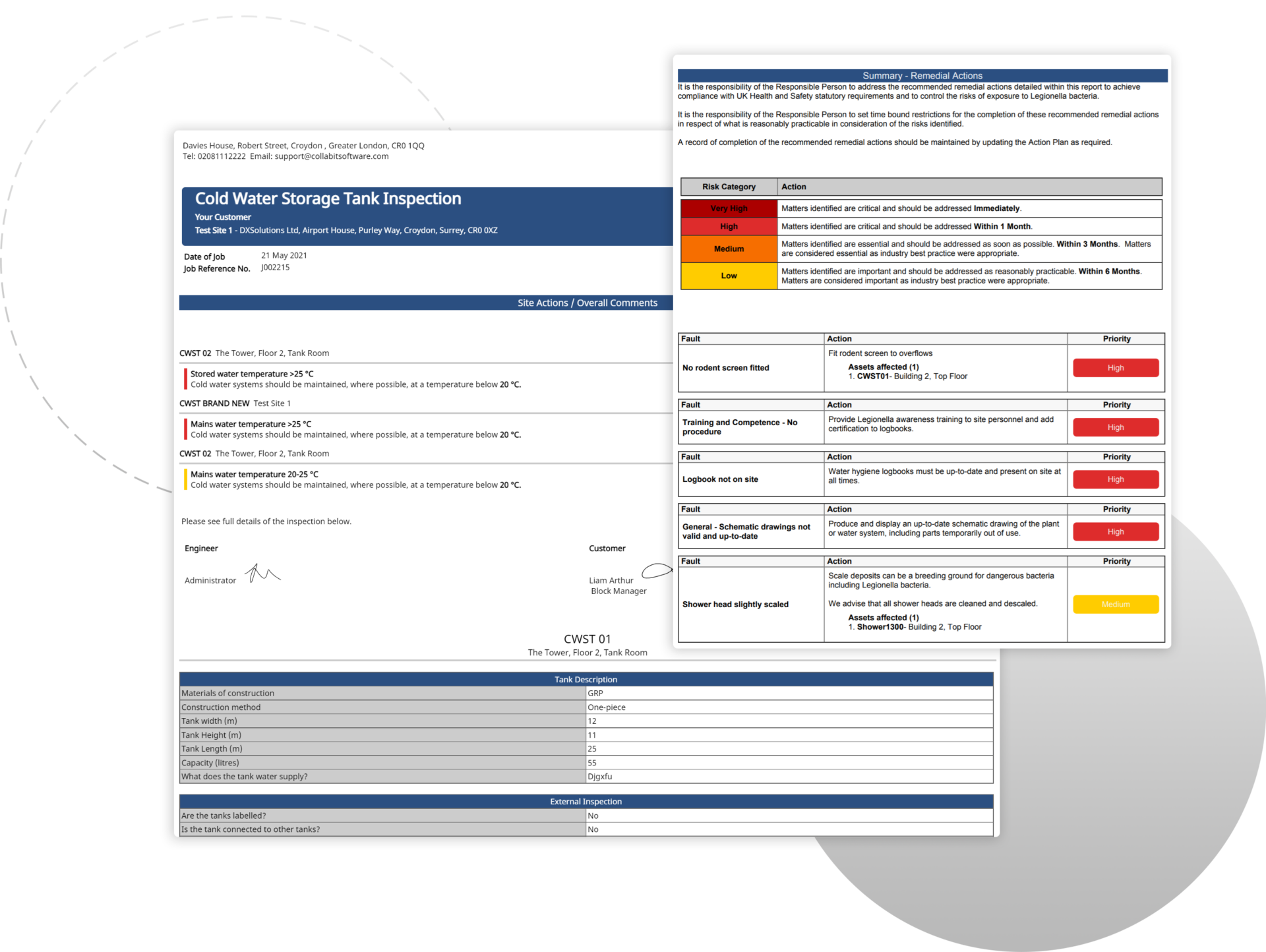

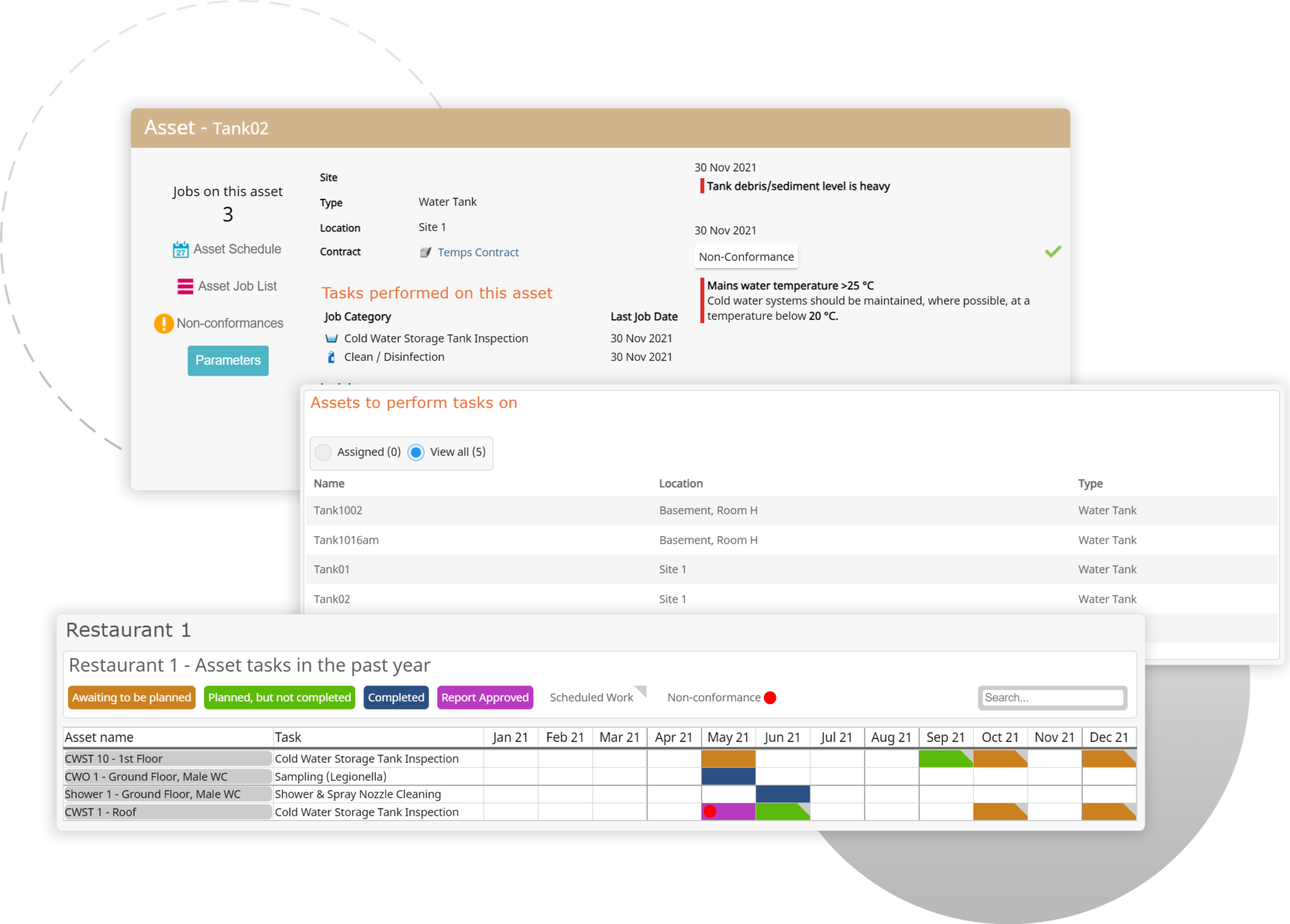

CMMS software examples – Landing Page CMMS

Onsite works and reports

What is a CMMS Software? CMMS for Every Business: The Verdict

An effective CMMS can save money and time by creating a more efficient maintenance plan. Surveys show that 70% of companies are not aware of when their equipment is due for maintenance. And this is a tool that solves problems before they emerge. For some businesses, the concept may be new, but the good news is – the systems are designed to work automatically with minimal training yet create significant returns on the investment.

There are numerous providers to get your CMMS journey started and Collabit stands out from its competitors.

Collabit offers some of the best CMMS solutions in the United Kingdom. The unique technologies best CMMS software Collabit Software uses can be easily adapted to niche industries, enabling consumers to tailor an efficient system that will boost their company’s efficiency.

Time is money, and the longer a piece of equipment functions without the need for repair, the bigger the profits. Trusting CMMS as a tool will ensure uninterrupted productivity and longevity of your business.